Air Lens Protection

Challenge:

Design a system to protect the lens of a camera/laser scanning device

Concept:

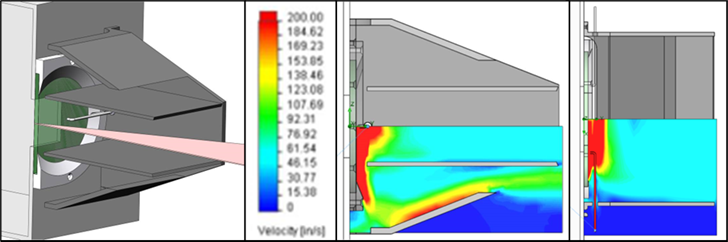

Create a high pressure/high velocity air boundary layer using compressed air and a shroud to direct air flow and provide secondary protection

Results:

An energy efficient system that protects the lens from debris and moisture

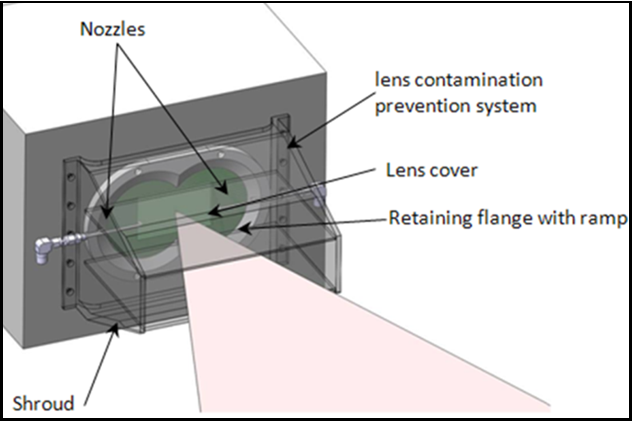

Capstan Technologies developed a system to prevent lens contamination of laser-based rail track inspection systems for the Federal Railroad Administration (FRA). The system includes a transparent, impact-resistant lens cover on the outside of the laser slit. An air nozzle directs a continuous, high-velocity air stream directly on and perpendicular to the outer surface of the lens cover. The air stream, upon contact with the lens cover, moves at high velocity outwardly along the lens cover surface away from the nozzle outlet. This advancing air stream forms an air film barrier over the lens cover surface. A small gap set between the nozzle outlet and the lens cover surface dictates the thickness of the air film barrier and directly influences the velocity of advance of the air stream.